Speed up your inspection processes while gaining complete visibility into each stages of the inspection process. Our AI-powered inspection management solution eliminates bottlenecks by automating routine tasks, ensuring compliance with regulations, and offering real-time data that helps your team conduct inspections more effectively allowing for a quicker decision.

Our QAI assistant delivers real-time insights, automates routine inspection tasks, and accelerates inspection processes by prioritizing inspections. This ensures more efficient inspections, reduces delays, and helps maintain high-quality standards across all operations.

If you have more questions feel free to reachout to us.

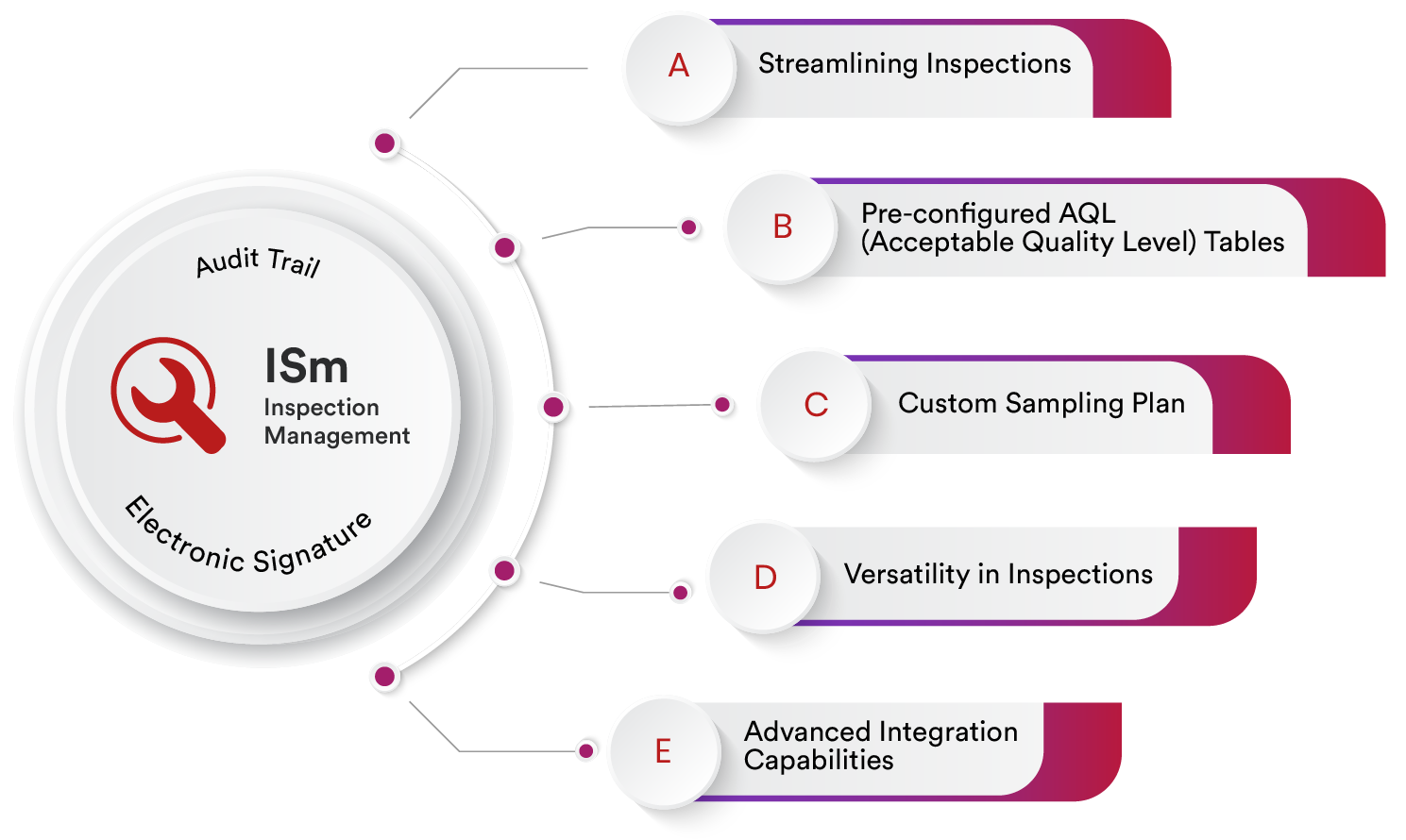

Contact UsQualityze Inspection Management is a cloud-based software solution that helps streamline, standardize, and manage inspection processes throughout different manufacturing stages. Whether conducting incoming, in-process, or pre-shipment inspections, Qualityze simplifies the process, making it easier to verify product quality before releasing it to consumers. It comes pre-loaded with internationally recognized standards such as ANSI/ASQC Z1.4 (ISO 2859-1), allowing you to ensure compliance while reducing the risks and costs associated with poor quality.

Qualityze Inspection Management helps establish robust inspection processes, ensuring product quality by providing tools to define sampling plans, inspection standards, and acceptance thresholds. It enables inspections across incoming materials, production stages, and pre-shipment checks. The system is also compliant with regulatory standards such as ISO 9001, FDA 21 CFR Part 11, and EU Annex 11, offering features like electronic records, e-signatures, and audit trails to maintain transparency and compliance.

With Qualityze Inspection Management, you can perform multiple types of inspections, including incoming inspections (materials arriving at the facility), production inspections (during the manufacturing process), and pre-shipment inspections (before final delivery to the customer). This holistic approach ensures proper quality management at all stages, reducing the likelihood of defects and minimizing the risk of non-conformance.

Key features of Qualityze Inspection Management include: - Sampling Plans: Supports ANSI/ASQC Z1.4 and custom sampling plans to identify sample size and acceptance thresholds. - Inspection Standards: Define inspection standards for different types of inspections like parts, suppliers, or products. - Switching Rules: Automatically switch between different inspection levels (normal, tightened, reduced) based on historical data. - Nonconformance Management Integration: Allows you to create Nonconformance (NC) records to manage quality issues identified during inspections. - ERP Integration: Seamlessly integrates with existing ERP systems for better tracking of purchase orders and material inspection.

Qualityze Inspection Management integrates seamlessly with your existing IT ecosystem, such as ERP systems, to complement your supply chain processes. Integration enables the use of purchase orders, work orders, and lot information directly during inspections, and the inspection data can be sent back to the ERP system for further actions, such as stock realization after successful inspections.

Qualityze Inspection Management provides advanced tools to help identify critical suppliers and mitigate risks. You can define different inspection standards, sampling plans, and severity-based AQL (Acceptable Quality Level) for each supplier based on their performance history. The automated switching rule adjusts inspection levels based on the supplier's performance, helping reduce risks and ensuring that only high-quality materials are used in production.

Severity-based sampling plans in Qualityze Inspection Management are used to enforce more stringent inspections of critical criteria of materials. With configurable workflows and forms, users can define AQL (Acceptable Quality Level) levels for each criterion based on its criticality, ensuring that only high-quality materials are allowed into production. This approach helps reduce product failures and guarantees compliance with industry standards.

Qualityze Inspection Management allows you to create multiple inspection standards that fit your organization’s needs. It categorizes inspection characteristics into attributes (such as pass/fail) and variables (nominal values and tolerances). With the in-built integration of Qualityze Document Management, you can easily document and reference drawings, SOPs, or any other related documents for seamless inspections.

Qualityze Inspection Management is designed to cater to various industries, including Hospitality, Manufacturing, Life Sciences, Pharmaceuticals, Medical Devices, Cannabis, Nutraceuticals, Biologics, Biotech, Food & Beverages, Automotive, Aerospace, Defense, and Logistics. It provides industry-specific inspection capabilities, ensuring compliance with applicable regulatory standards, and helps organizations manage quality inspections efficiently, regardless of the industry.

Calculate your potential savings with our ROI Calculator

ROI Calculator